Select your location

Bosch Rexroth around the world

Asia & Pacific

Europe

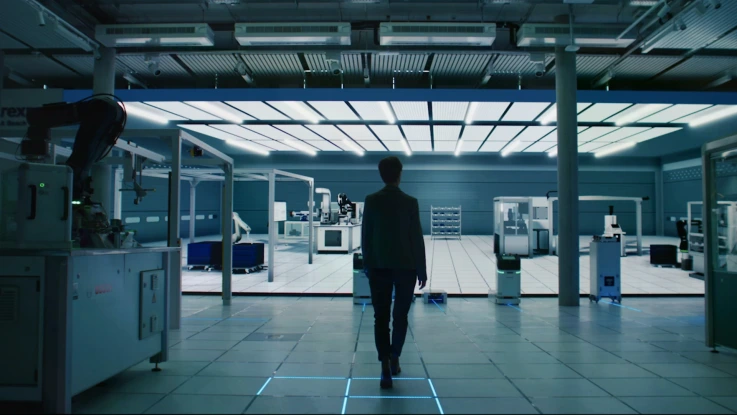

“Digital transformation brings new ways of collaboration, along with the ability to streamline processes. It allows information to flow more efficiently,” says Eva Seidel, Chief Digital Officer – Change Business.

Digital Transformation: Embracing the Power of Software

Digitalization is transforming the way we work, operate mobile machinery, and run factories, with a shift from hardware to software. At Bosch Rexroth, we support our customers in this transformation, aiming to increase productivity and sustainability. We transfer our expertise in dynamic and precise movement to the virtual world of software-driven automation.