Discover the CU.BE, our model factory and innovative products live

CU.BE Ulm – Model Factory

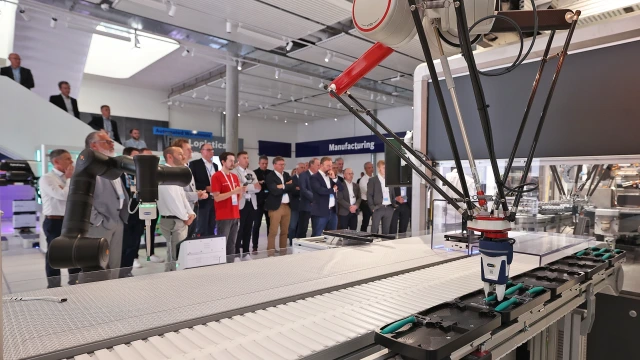

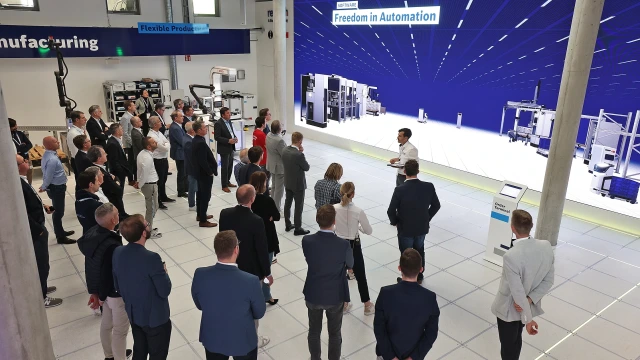

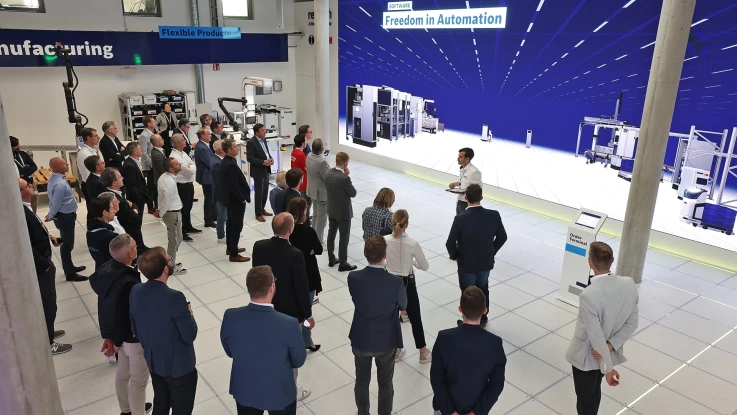

A flexible, productive and smart factory is not just a beautiful vision, it can already work: Our ModelFab at the Bosch Rexroth customer centre CU.BE in Ulm demonstrates this. The 500 square metre value stream set up there as an example illustrates how existing production environments can also be transformed safely and cost-effectively. Find out more about sustainability in factory automation, flexible material flow and the benefits of modular software architecture.

Innovation meets reality in the model factory

Based on concrete use cases and real production scenarios, including intralogistics and distribution, we present our powerful yet practical portfolio. Experience market-ready products in combination with innovations from Bosch Rexroth. This will give you a real feel for how versatile the manufacturing of the future can be. You can see impressions of the re-opening in Ulm in the video on the right.

Modellfabrik - Deep Dives

Tauchen Sie ab in die Technik - mit unseren DeepDives! Neben einem Überblick über die gesamte Wertschöpfungskette, bietet Ihnen unsere Modellfabrik auch exklusive Einblicke in modernste Prozesse und Technologien. Nutzen Sie die Gelegenheit in produkt- und themenspezifischen Deep Dives um moderne Automationsprozesse und innovative Lösungen detailliert zu analysieren und sich mit unseren Experten auszutauschen. Vereinbaren Sie jetzt einen Termin und erleben Sie die Zukunft der Produktion live. Unser Vertriebsteam steht Ihnen für weitere Informationen gerne zur Verfügung.