Products

OverviewIndustries

Overview- Agriculture and Forestry

- Automotive

- Battery production

- Chemical processing

- Construction and Infrastructure

- Consumer goods

- Energy and Utilities

- Healthcare

- Hydrogen

- Logistics and Transport

- Materials and Resources

- Pharmaceutics

- Recycling and Waste handling

- Renewable energies

- Semiconductors and Electronics

- Testing Technology

Service

OverviewCompany

OverviewBuy

OverviewProduct groups

OverviewEngineering

OvervieweConfigurators and Tools

OverviewJob opportunities

OverviewEDI (Electronic Data Interchange)

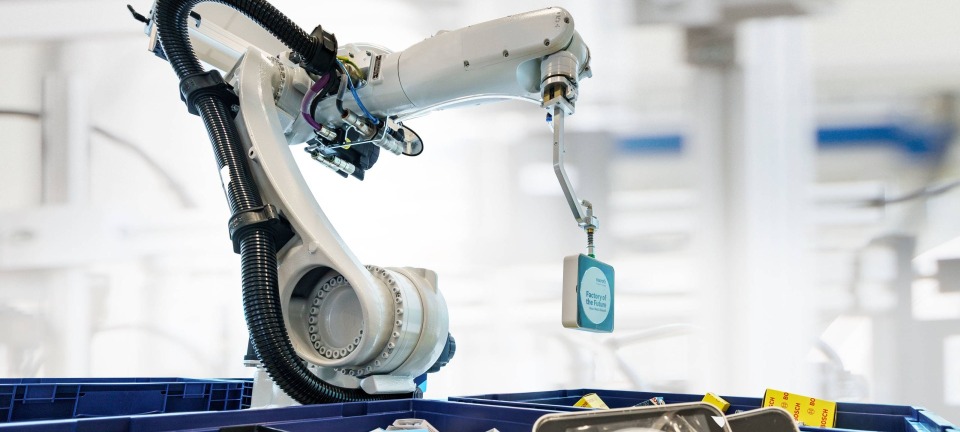

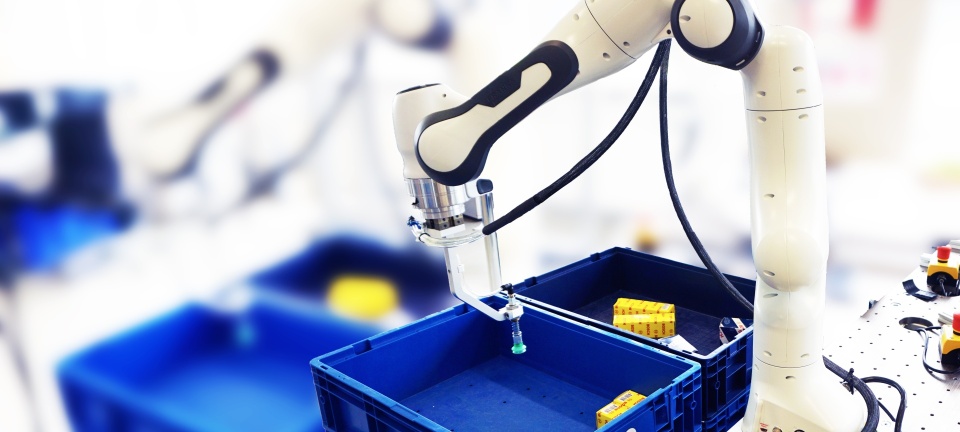

OverviewSmart Item Picking – toolkit for autonomous handling

Rising labor shortage, increased ergonomic requirements and growing expectations in eCommerce require automated solutions for intralogistics. Robotics enables the flexible use of systems and skills in automation, but until now integrators have had to adapt the robots to the environment and tasks.

Software tools for automated handling in intralogistics

Automation without robotics and robotics without artificial intelligence (AI) are no longer conceivable in the medium term. This is why Bosch Rexroth has developed the AI-based software toolkit for autonomous handling. This enables industrial robots to perceive and understand their environment and adapt independently to changing tasks.

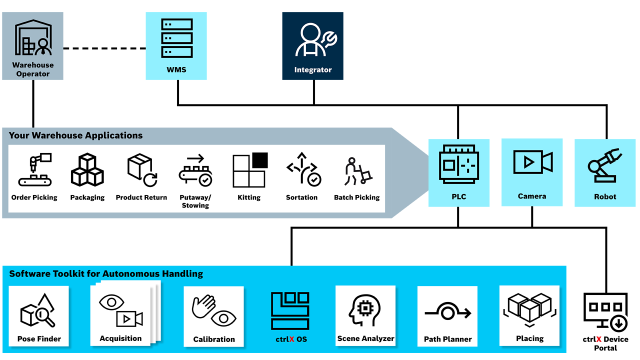

An ecosystem of partners for manufacturer-independent integration

The application-specific requirements for the integration of robot systems are diverse and require individual solutions and the expertise of various disciplines - from computer vision to robot control and manipulation control. To support integrators in this challenge and offer the best solutions for all components, Bosch Rexroth relies on a partner network of solution component providers.

The "Open Innovation Network" supports a wide range of solutions and covers a broad spectrum of use cases. Thanks to an open, component-based architecture, integrators are able to develop intelligent applications and integrate optimal, manufacturer-independent solutions for end users. Bosch Rexroth relies on the existing ctrlX World partner network for this.

Live demonstration

Visit us for a free product presentation in our model factory in Ulm, Germany, and experience our toolkit for automated handling in action!