Products

OverviewIndustries

Overview- Agriculture and Forestry

- Automotive

- Battery production

- Chemical processing

- Construction and Infrastructure

- Consumer goods

- Energy and Utilities

- Healthcare

- Hydrogen

- Logistics and Transport

- Materials and Resources

- Pharmaceutics

- Recycling and Waste handling

- Renewable energies

- Semiconductors and Electronics

- Testing Technology

Service

OverviewCompany

OverviewProduct groups

OverviewEngineering

OvervieweConfigurators and Tools

Overview- Home

- Products

- Product groups

- Tightening Technology

- Press-Fit System

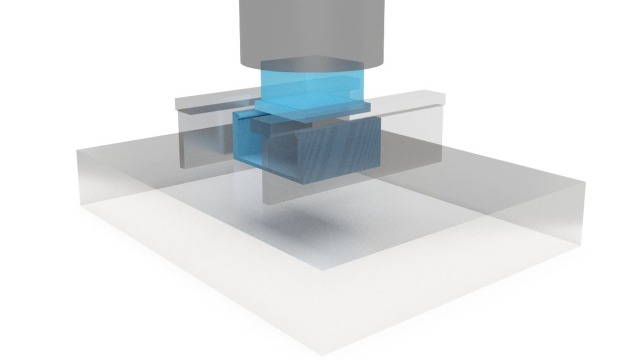

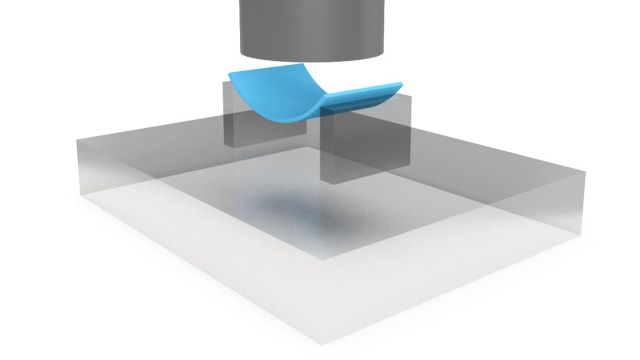

The Press-Fit System. A new world of joining technology.

POWER YOUR PROCESSES with the Press-Fit System from Bosch Rexroth

Discover the new Press-Fit systems: impressive complete solutions with smart mechatronics.

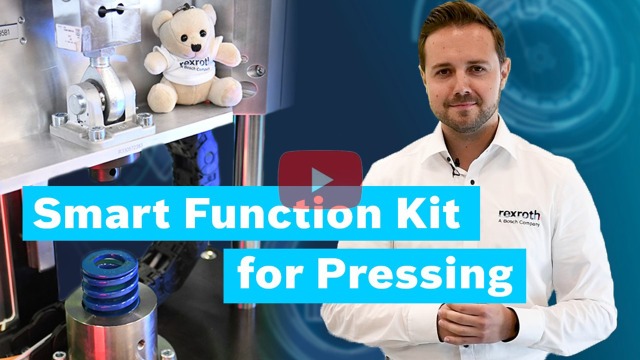

The Press-Fit system is characterized by numerous advantages to minimize time and costs during integration and commissioning. It is pre-assembled, ready to plug in and fully parameterized to allow the pressing process to be set up directly via the web interface. This enables quick and uncomplicated setup. The use of standard components such as the Smart Function Kit from Bosch Rexroth also facilitates the availability and procurement of spare parts.

You can rely on efficient and smooth integration into your application with our state-of-the-art Press-Fit systems.

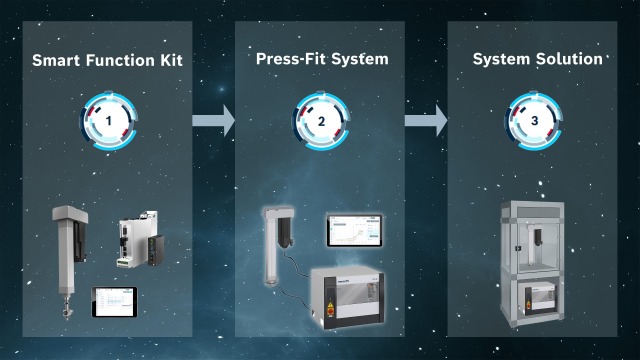

The Three Levels of the Smart Presses Integration

More about Press-Fit System

Press-Fit System Overview

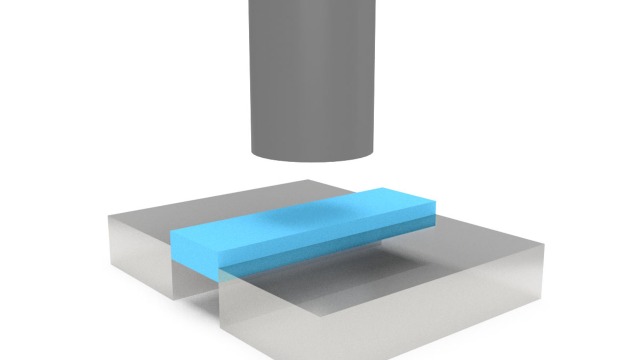

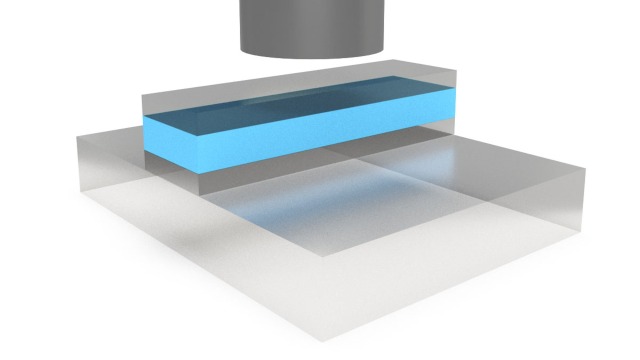

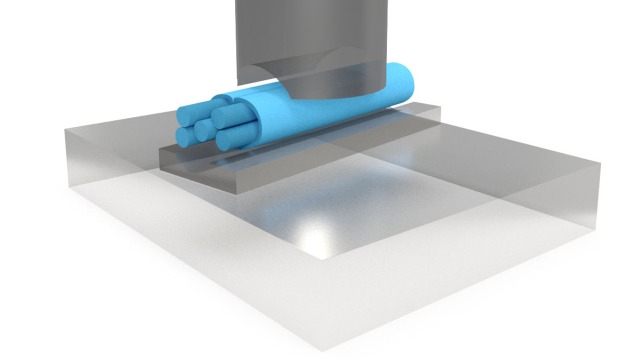

Press-Fit System Applications

Press-Fit System Catalog

Get the complete overview of the Press-Fit systems.

The catalog contains:

- Information on the Press-Fit systems in various sizes

- Information on components, software and commissioning

- Order information

- Dimension drawings